Home > Capabilities > Research & Development > Process & Product Development

Process & Product Development

Unlike small molecules that are chemically synthesized, protein therapeutics are produced from living organisms, including microbes or cells, making them highly complex to manufacture consistently and reliably.

Biocon Biologics’ core expertise lies in the development and manufacture of biosimilars, a class of biologics that offers life-changing and cost-effective therapies. Over the course of four decades, we have leveraged innovative scientific capabilities and cutting-edge manufacturing infrastructure to advance our biosimilars product pipeline for the benefit of patients.

Biosimilars: Process Development

Cell Line Development

Our expertise spans both microbial and mammalian platforms to express desired therapeutic proteins. Mastery of fermentation technology led to the development of our differentiated, proprietary Pichia pastoris technology platform, which is currently used to develop and manufacture all our insulins and insulin analogs.

The extensive production of therapeutic monoclonal antibodies (mAbs), targeting oncology and anti-inflammatory conditions, is achieved using mammalian cell lines, such as Chinese Hamster Ovary (CHO) and NS0 and SP2/0.

Cell Culture & Purification

Our process development capabilities span fermentation, purification and formulation, complemented by state-of-the-art analytical tools that allow us to identify and develop the best candidate at high quality. Constant innovation enables the optimization of cell culture conditions, fermentation and purification processes to ensure high purity in drug substances. Our manufacturing facilities are equipped with several large-scale bioreactors and state-of-the-art purification systems that ensure adherence to stringent safety and quality control standards.

Drug Product Development

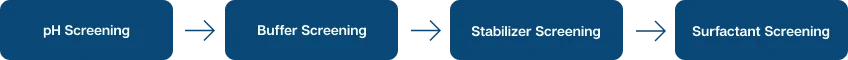

Our scientists bring a wealth of experience and expertise to the formulation of drug products. Extensive studies are undertaken to screen excipients and buffers, and optimize the process in order to develop a stable product of highest quality. Compatibility with primary packaging materials (vials, cartridges, prefilled syringes) is also evaluated as part of drug product development.

*Excipients added to a parenteral formulation must be chosen based on stability evaluation of the drug, after addition of a particular excipient

We develop low- and high-concentration biosimilars, either in liquid or lyophilized form. Products formulated in the laboratory are further characterized using analytical tools, in R&D.